- CNG & LPG Products

- CNG & LPG Products

- CNG Dispensers

- Priority Panels

- LPG Dispensers

- Payment Terminals

- Payment Terminals

- PT1

- PT2

- PT1 V2 with colour screen

- Pumps & Dispensers

- Unattended Refuelling

- Fuel Management

- Tank Kits, Tank & Rack Dispensers, Flow Meters

- Tank Kits, Tank & Rack Dispensers, Flow Meters

- Tank kits

- Tank Dispensers

- Rack Dispensers

- Flow Meters

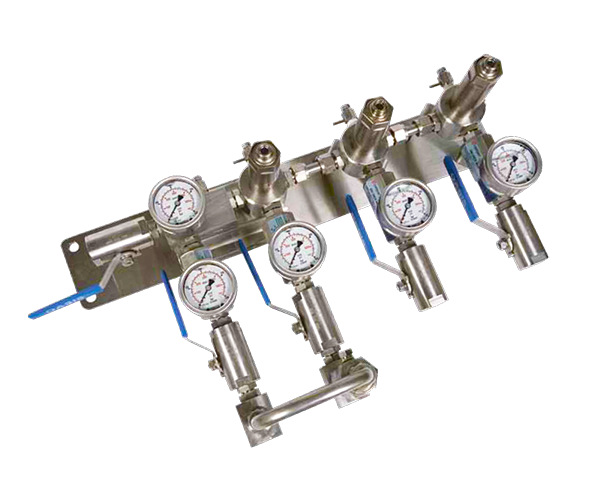

Compac Priority Panels are designed around our own extremely reliable and robust Priority Valve.

There are clear benefits gained when you install a Compac Priority Panel:

- Manufactured from High Quality Stainless Steel ensuring maximum corrosion resistance and long service life

- Ultra High Flow Rates – The panels are designed for compressor flow rates in excess of 3,000 m³/hr

- No Reverse Flow – The check valves on each line prevent reverse flow through the priority panel

- Easy Maintenance – The station can be kept running while the manual isolation valves are shut for maintenance work. Pipework does not need to be removed for servicing the panels

- Simple Operation – The Priority Valves only open once the inlet pressure reaches 230 bar. Gas is then allowed to flow to the common outlets on the bottom and right hand side of the valve. When all banks reach 230 bar, they fill up together until the compressor shuts off

Before dispatch all Compac Priority Panels are tested, this ensures that on arrival your priority panel is ready to use and no additional on-site adjustments are required.

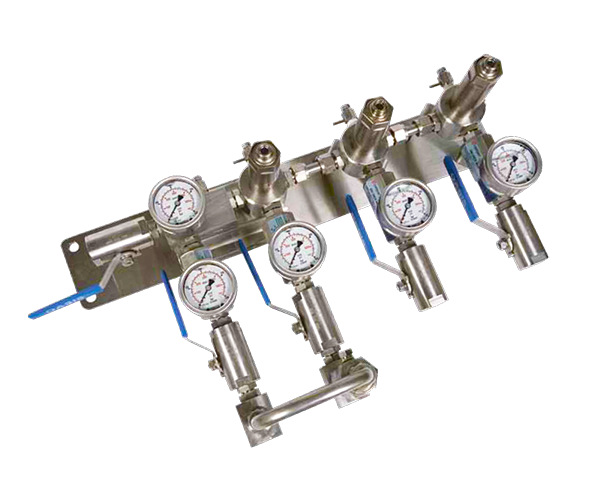

Compac Priority Panels are designed around our own extremely reliable and robust Priority Valve.

There are clear benefits gained when you install a Compac Priority Panel:

- Manufactured from High Quality Stainless Steel ensuring maximum corrosion resistance and long service life

- Ultra High Flow Rates – The panels are designed for compressor flow rates in excess of 3,000 m³/hr

- No Reverse Flow – The check valves on each line prevent reverse flow through the priority panel

- Easy Maintenance – The station can be kept running while the manual isolation valves are shut for maintenance work. Pipework does not need to be removed for servicing the panels

- Simple Operation – The Priority Valves only open once the inlet pressure reaches 230 bar. Gas is then allowed to flow to the common outlets on the bottom and right hand side of the valve. When all banks reach 230 bar, they fill up together until the compressor shuts off

Before dispatch all Compac Priority Panels are tested, this ensures that on arrival your priority panel is ready to use and no additional on-site adjustments are required.

Solenoid Shut-off Option

With the addition of Compac Solenoid Valves each of the forecourt lines can be shut-off. The solenoids come pre-wired into a flameproof box and when the power supply is removed the solenoids close instantly. This additional safety feature provides increased control of the gas flow through your priority panel.

Solenoid Shut-off Option

With the addition of Compac Solenoid Valves each of the forecourt lines can be shut-off. The solenoids come pre-wired into a flameproof box and when the power supply is removed the solenoids close instantly. This additional safety feature provides increased control of the gas flow through your priority panel.

We offer a range of Priority Panels with options designed to suit your specifications:

- One, Two, and Three Bank Priority Panels

- Optional Compressor Top-Up

- Optional Solenoid Shut-off Valves

- Optional Pressure Relief Valves

- Daughter Station Priority Panel

- Other options are available on request

We offer a range of Priority Panels with options designed to suit your specifications:

- One, Two, and Three Bank Priority Panels

- Optional Compressor Top-Up

- Optional Solenoid Shut-off Valves

- Optional Pressure Relief Valves

- Daughter Station Priority Panel

- Other options are available on request